Today, there are less than 50 master coopers in the entire country. These are the men and women who are highly skilled in the craft of barrel-making, having gained the skills and abilities of this art through years of labor at “the block” as the coopers say.

Today, more and more wineries and distillers have invested more in the barrel making process, as barrels are considered a crucial part of the product’s style. Keep reading to learn more about the barrel making process here and learn why it is still important today.

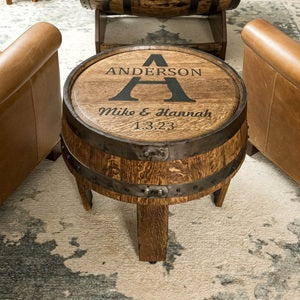

The Parts of the Barrel

There are several important components of a barrel. These include:

- Hoops: These are the metal rings that surround the barrel and that are attached using rivets.

- Head: The two flat portions of the barrel, which are usually stamped with a logo, are the heads. Most American oak barrel heads have been toasted, but French oak barrel heads aren’t.

- Bilge: This is the widest portion of the barrel.

- Stave: A single wooden strip used for making a barrel.

- Bung Hole: This is the small opening in the barrel and is usually closed using in a stopper, which allows someone to sample the wine or whiskey inside and that allows the liquid to be moved from one barrel to another, which is called racking.

Now that you know the parts of the barrel, you can learn more about the steps in the assembly process.

Set-Up

The proper staves are selected for the barrel. The sap, wormholes, knots, grain, and the pattern on the grain will be inspected carefully. Each barrel will have a specific number of staves, depending on the size, that is arranged in a specific pattern. The setup is somewhat of a puzzle, as each stave may vary in width, but barrels cannot have any gaps.

Bending the barrel

To create the shape of the barrel, the staves that are used must be warmed over an open fire. Once the exterior of the barrel has reached a certain temperature, temporary hoops will be put in place by a hydraulic machine to force it into the proper shape.

Toasting

The newly shaped barrel will go back into the fire for toting. This will take approximately 40 minutes – depending on the desired color. This helps to crystalize the natural sugars in the wood. Once complete, the barrel is capped with the round barrel head.

Hooping

The temporary hoops put on the barrel will be removed and the permanent ones will be applied. Before securing the new hoops to the barrel, the surface will be sanded, and then the hoops will be connected.

There’s no question that the wine or whiskey barrel is an important part of the product. Having a bit of insight into how these are created can help you see how and why this is considered an art form today. It is something that makes it easy to know what is inside, what company produced it, and is an aesthetically pleasing container for the wine and whiskey.